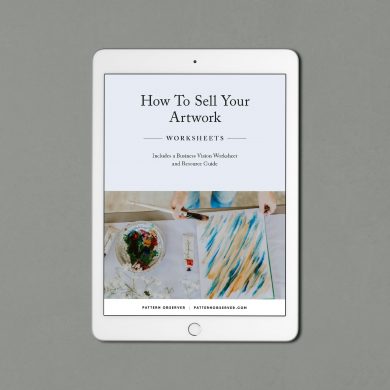

There’s a good chance you’ve designed, pinned, or admired a floral pattern this week. Maybe it was trailing vines on a cream ground, or a tree heavy with blooms, or pomegranates beside flowers that don’t exist anywhere but in pattern. If so, you’ve been looking at something much older than you might realize.

That aesthetic we call “classic English floral”? It isn’t English at all. It’s Indian. And the story of how it traveled from India to your Pinterest board is one every textile designer should know.

This is the story of chintz.

The Fabric That Drove Europe Wild

In the seventeenth century, European traders sailing to India for spices discovered something that would prove even more valuable: cloth. Indian artisans along the coast had perfected techniques for dyeing cotton that no one in Europe could replicate. The colors didn’t run. They didn’t fade. They got more beautiful with washing.

The word chintz comes from the Hindi word chint, meaning spotted or variegated. What arrived in European ports were lengths of cotton alive with birds, flowering trees, and botanical gardens rendered in vivid reds, blues, and greens.

At the time, european printed fabrics were dull by comparison, and colors washed out or bled into each other. Indian chintz was colorfast because of a complex dyeing process involving mordants and metallic salts that bonded dyes permanently to cotton fibers. The technique had been refined over centuries and required very specific knowledge, such as which roots produced which reds, how long to soak the cloth, when to apply the wax resist, and how many days to leave it in the sun.

A single piece of chintz could take weeks to complete and pass through the hands of eight to ten specialized artisans. It was slow, skilled work—the opposite of mass production.

And Europe wanted it desperately.

When Florals Were Contraband

By the 1680s, more than a million pieces of chintz were being imported into England each year. The fabric was everywhere: bed hangings, curtains, dresses, and upholstery. The obsession was so complete that it threatened domestic industries. English and French textile makers, who were using wool and silk, couldn’t compete with cotton’s lightness or Indian artisans. Therefore, they demanded protection.

What followed was remarkable: European governments began banning chintz.

France prohibited the import and production of printed cotton in 1686. England followed with the Calico Acts of 1700 and 1721, making it illegal to wear or use Indian chintz. Smugglers faced fines; repeat offenders risked prison. The fabric became contraband.

But desire doesn’t disappear because of legislation. Even at Versailles, fashionable young aristocrats wore chintz anyway, technically outside the law. The ban drove innovation: if you couldn’t import the finished fabric, you could import plain cotton and print it yourself. European manufacturers raced to crack the Indian dyeing code.

In 1734, a French naval officer stationed in Pondicherry began sending home letters detailing what he observed of the chintz-making process, along with fabric samples from each stage. A few years later, a French missionary named Father Coeurdoux supplied additional technical details while attempting to convert Indian artisans to Christianity. These industrial secrets, extracted and transmitted, helped European manufacturers finally produce their own colorfast prints.

By the time England repealed its chintz ban in 1774, British mills were ready. They could make something that looked like chintz, not with bamboo pens and months of patient handwork, but with copper rollers and mechanical speed.

What Got Lost

When British mills began mass-producing chintz imitations, something fundamental changed. The mechanical process was faster and cheaper, which made floral cotton available to a much wider market.

But the imitations weren’t the same. They couldn’t be. The hand of the artisan, the regional variations, the small decisions that made each piece unique, all of this was smoothed away in the name of efficiency. The flowers that had been drawn by human hands with bamboo pens were now stamped by machines. The colors that had emerged through weeks of careful dyeing became uniform and predictable.

Meanwhile, the Indian textile industry, which had once produced a quarter of the world’s cloth, was systematically dismantled. British colonial policy imposed tariffs that made it nearly impossible for Indian textiles to compete. Raw cotton was exported to English mills; finished goods were shipped back to India and sold.

By the early twentieth century, the word “chintzy” had become an insult, meaning cheap, gaudy, or in poor taste. The term was applied not to the original Indian textiles, which remained rare and valuable, but to the mass-produced imitations that had flooded the market. A fabric tradition that represented centuries of accumulated knowledge and artistry had been reduced to a word describing tackiness.

The Patterns We Inherit

The trailing vines and the abundant florals are visual languages developed by Indian artisans and then so completely absorbed into the Western design vocabulary that their origins became invisible.

Knowing where a visual language comes from changes how we use it. It invites us to look more closely at the archive images we reference, at the “vintage” prints we love, at the assumptions we carry about what looks “traditional” or “timeless.” Who made the original? Under what conditions? What was lost when it was copied?

These questions don’t have to inhibit what we create. But they can inspire us, and deepen our connection to the work we make.

The Textile Design Lab explores design history as part of our commitment to helping designers develop work that’s both commercially successful and creatively grounded. Our Style Lab includes design history resources alongside trend forecasting and style d